Windshield Wiper Arm Removal & Repair

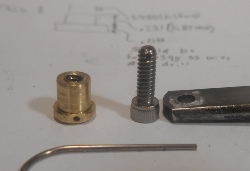

Brass replacement shaft with head to replace the rivet. It is attached with a 6-

The was assembled to the arm then drilled. It was then disassembled and reassembled to the top piece and the wire inserted. The wire insertion required running the drill through the hole again as I was unable to get it lined up good enough to insert the wire. A better way would have been to drill the hole after final assembly.

Serrated shaft that wiper arm goes onto. Note the small pin sticking up -

Wiper arm retainer retainer clip visible at right of socket.

Note the rounded edge on the retainer clip -

Knowing that the clip does not have to be moved, I used an open end wrench to pry up on the arm being careful to NOT hit the pin sticking up next to the serrated shaft & being sure to have the sides of the open end engage the sides of the wiper arm socket.

Wiper blade on wiper arm

Top piece of wiper arm after rivet head ground off and punched out.

The rivet body serves as a shaft and appears to be round with no wear which suggests hardened steel.

The hole in this top piece was oval, so it was drilled out with a “D” sized drill to make it round. This leaves room to ream 1/4” if premature wear occurs from the rough walls of the drilled hole.

Finished arm showing the cap screw.

Finished arm -

Importants Notes:

1. The ss screw end is recessed so that it cannot contact the windshield if the wiper blade comes off.

2. The brass flange is domed and polished to reduce chances of scratching the windshield if the wiper arm comes off.

Finished arm -

Reinstellation of the arm is a major pain unless you insert a pin into the hole to hold the internal socket casting in its approximate final position.

The pin is a piece of 3/32 rod with a handle to prevent losing it.

Problem:

Wiper was leaving severs streaks due to the arm not keeping the wiper blade vertical to the windshield.

Cause was excess play in the bearing that connects the top piece of the wiper arm assembly to the large wiper arm.

Problem was solved by replacing the rivet which serves as the shaft that connects the top piece to the arm as shown below. The amount of play in the bearing is now about the same as a friend’s fairly new car.

I am waiting for the rain to return to give this a good test.

This is NOT the type of retainer clip found on my car.

I have no idea if it has to be pulled away from the shaft before removal